Profile area "Sustainable materials, processes and products"

Climate protection and resource conservation are key tasks for our society. The natural sciences and engineering can contribute to this by working on solutions for new materials (metals, polymers and the combined hybrids), material-specific construction, joining and manufacturing processes, specific production and simulation processes or in the field of sustainable energy supply.

In order to cover this enormous breadth of research, Paderborn University's "Sustainable Materials, Processes and Products" profile area brings together interdisciplinary research from Mechanical Engineering, Chemistry, Physics and Electrical Engineering.

Key technologies

Application-orientated and basic research combined

Application-oriented research is driven forward in proven partnerships between science and industry and complements excellent basic research, for example in the field of method or material development. Research is also carried out in long-term projects in supra-regional and international networks.

In Paderborn, the researchers utilise the modern infrastructure of the ILH and DMRC - Academic and are integrated into an extensive research network.

Interdisciplinary research institutions

The aim of the ILH is to take a holistic view of lightweight construction and to address issues relating to the entire life cycle of a component. The DMRC - Academic (Direct Manufacturing Research Center (DMRC) - Academic) brings together outstanding expertise in additive manufacturing as a special manufacturing process with high lightweight construction potential. The Competence Centre for Sustainable Energy Technology(KET) develops approaches and methods aimed at achieving a sustainable energy supply for the electricity, heating, industry and transport sectors.

Das ILH ist eine zentrale wissenschaftliche Einrichtung der Universität Paderborn. Hier werden gezielt die Expertisen von elf Gruppen aus den Fachdisziplinen Maschinenbau, Chemie und Physik gebündelt, um neue Hybridsysteme aus verschiedenartigen Materialien zu entwickeln und erforschen. Durch anwendungsorientierte Forschung entstehen innovative Leichtbaukonzepte. Prototypen und Demonstratoren werden zusammen mit Industrie entwickelt und sichern die Realisierbarkeit ab. Die Grundlagenforschung beschäftigt sich mit der skalenübergreifenden Entwicklung von Methoden und Materialien.

In hybriden Multimatrialsystemen werden leistungsfähige Materialien wie z. B. ultrahochfeste Stähle mit Kohlenstofffaser-Kunststoff-Verbunden (CFK) intelligent kombiniert. Voraussetzung für die Entwicklung derartiger Werkstoffverbindungen ist die Analyse von Materialeigenschaften und -Grenzflächen sowie die Betrachtung der Fertigungsprozesse mit neuen Materialstrukturen. Dafür steht im ILH ein breit aufgestelltes Team von Forscher*innen und eine moderne Infrastruktur bereit.

Mehr Informationen finden Sie auf der Website des Instituts.

Das Direct Manufacturing Research Center (DMRC) - Academic, ein an der Universität Paderborn angesiedeltes Transferinstitut, forscht daran, die additive Prozesskette als robustes industrielles Produktionsverfahren zu etablieren. Hier arbeiten technologieführende Industrieunternehmen Hand in Hand mit Forschern der Universität an der Industrialisierung der additiven Fertigung. Die gesamte additive Wertschöpfungskette von der Rohstoffgewinnung über die Fertigung bis zur Anwendung wird sowohl von großen als auch von kleinen und mittelständischen Unternehmen abgedeckt. Die Struktur des DMRC ist sehr flexibel und interdisziplinär; je nach den aktuellen Forschungsthemen kann die Konstellation der am DMRC beteiligten Lehrstühle verändert werden.

Derzeit arbeiten im DMRC 11 verschiedene Lehrstühle und eine große Anzahl von wissenschaftlichen Mitarbeitern zusammen.

Je nach Fragestellung und Zeithorizont finanzieren die Industriepartner des DMRC oder öffentliche Förderorganisationen Forschungsprojekte, die dann an der Universität Paderborn durchgeführt werden. Die im DMRC-Konsortium gemeinsam finanzierten Projekte werden dabei von den Industriepartnern gesteuert und kontrolliert. So können alle Partner den größtmöglichen Nutzen im Hinblick auf die Industrialisierung der DMRC-Forschungsergebnisse erzielen.

Mehr Informationen finden Sie auf den Seiten des Instituts:

Direct Manufacturing Research Center (DMRC) – Academic | Universität Paderborn

Das Kompetenzzentrum für Nachhaltige Energietechnik (KET) wurde im Januar 2012 als eine Zentrale Wissenschaftliche Einrichtung der Universität Paderborn gegründet. Die Aufgaben des KET sind Forschung, Lehre und Technologietransfer auf dem Gebiet der umweltfreundlichen und innovativen Energieerzeugung, Wandlung und Nutzung.

Die Ausrichtung und Kompetenzen der im KET kooperierenden fünf Fachgebiete und Lehrstühle der Elektrotechnik und des Maschinenbaus ermöglichen die interdisziplinäre Entwicklung fachübergreifender Lösungen energietechnischer Herausforderungen aus einer Hand.

Als Schnittstelle zwischen Industrie und universitären Forschungseinrichtungen richtet sich das KET an institutionelle und industrielle Anwender und bietet umfassende Kooperationsmöglichkeiten durch Beratung, Entwicklung, Simulation und Umsetzung im Bereich moderner Energietechnik.

Auf der Grundlage des Wissens und der Erfahrung der am KET beteiligten Partner stehen aktuelle Erkenntnisse aus dem Bereich innovativer Energietechnik zur Verfügung.

Mehr Informationen finden Sie auf der Website des Instituts.

Selected projects in the profile area

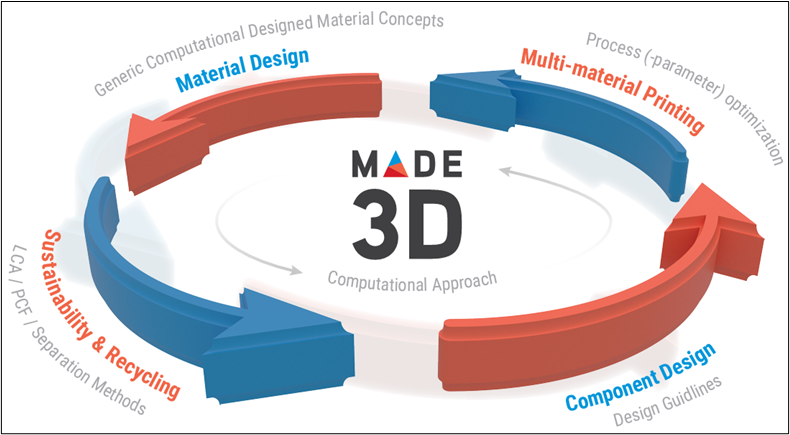

Die additive Fertigung (AM) hat das wirtschaftliche Potenzial, herkömmliche Fertigungsverfahren zu ergänzen, insbesondere bei der Herstellung komplexer Multimaterial-Bauteile. Um die Vorteile optimierter Leichtbaustrukturen voll ausschöpfen zu können, müssen in der Regel mehrere Werkstoffe mit unterschiedlichen physikalischen Eigenschaften verwendet werden. Dennoch sind Multimaterialkombinationen aus konventionellen Verfahren aufgrund von Eigenspannungen, Rissen oder thermischen Ausdehnungsraten der verschiedenen Materialien nicht auf AM übertragbar. Außerdem sind geometrische Form- und Lagetoleranzen sowie Recyclingstrategien für Pulverabfälle, nachbearbeitete Abfälle und das Bauteil selbst noch nicht definiert. Basierend auf den 3D-Druckverfahren PBF-LB und DED zielt das Projekt „MADE-3D“ (Multi-Material Design using 3D Printing) auf die gleichzeitige Entwicklung verarbeitungsfähiger, multimaterialoptimierter Legierungen, die Entwicklung von Designkonzepten für Multimaterialstrukturen mit spezifischen Simulationen für Lastfälle und Topologieoptimierungen, sowie eine umfassende Prozessanpassung. Die Legierungs- und Prozessentwicklung wird durch fortschrittliche integrierte rechnergestützte Materialentwicklungsansätze unterstützt, die Thermodynamik-, Mikrostruktur- und Prozesssimulationen durch maschinelles/aktives Lernen kombinieren, was zu kürzeren Materialentwicklungszyklen führt. Bei Massen- und Pulverwerkstoffen wird das Recycling von Multimaterialkomponenten durch innovative Konzepte die Nachhaltigkeit der additiven Multimaterialfertigung fördern. Diese Anpassung wird zu einer erhöhten Prozesssicherheit und -geschwindigkeit führen und die Verbreitung der Multimaterial-Fertigung in der gesamten Industrie ermöglichen. Das Projekt wird für die nächsten dreieinhalb Jahre mit rund 6,7 Millionen Euro im „Horizon Europe 2022“-Programm der Europäischen Union gefördert. Das Konsortium, bestehend aus Forschungseinrichtungen, Marktführern der additiven Fertigung, Luft-/ Raumfahrt, Automobiltechnik und Start-ups, bringt ein breites Spektrum internationaler Expertise mit: Projektpartner sind neben der Leitung der Universität Paderborn: SLM Solutions; das Fraunhofer Institut für Gießerei-, Composite- und Verarbeitungstechnik IGCV (alle drei aus Deutschland); die Universität der Ägäis (Griechenland); f3nice (Italien); Exponential Technologies (Lettland); QuesTek Europe (Schweden); AVL List (Österreich); Skyrora (Großbritannien); Safran Additive Manufacturing Campus; Commissariat à l’énergie atomique et aux énergies alternatives CEA (beide aus Frankreich); Amires(Tschechien) und das Centre Suisse d’Electronique et de Microtechnique CSEM (Schweiz).

Im Projekt „Climate neutral Business in Ostwestfalen-Lippe (Climate bOWL)“ arbeiten Wissenschaftler*innen der Universität Paderborn, vertreten durch den Software Innovation Campus Paderborn und das Fachgebiet Leichtbau im Automobil, mit der Universität Bielefeld und den Praxispartnern Miele, GEA, Phoenix Contact sowie NTT Data interdisziplinär zusammen, um Unternehmen bei der Erreichung von Klimaschutzzielen zu unterstützen. Auf dem Weg zur Klimaneutralität bedarf es einer ganzheitlichen Herangehensweise, die ressourceneffizient die Aggregation und Bewertung von Treibhausgasemissionen (THGE) sowie die Identifizierung und Priorisierung von THGE-Reduktionsmaßnahmen ermöglicht. Dieser Herausforderung nimmt sich das Projekt Climate bOWL mit der Entwicklung eines digitalen Assistenzsystems an, welches Unternehmen bei der standardisierten und automatisierten Datenerhebung sowie bei der Identifizierung von Effizienzpotentialen unterstützt. Das Projekt wird im Rahmen des Spitzenclusters „it’s OWL“ seit April 2022 mit 1,86 Millionen Euro vom Ministerium für Wirtschaft, Innovation, Digitalisierung und Energie des Landes Nordrhein-Westfalen gefördert, das Gesamtvolumen des Projektes beträgt 3,16 Millionen Euro.

Projektkoordination: Dr.-Ing. Florian Schlosser | Software Innovation Campus Paderborn | FG Energiesystemtechnik