Initial situation

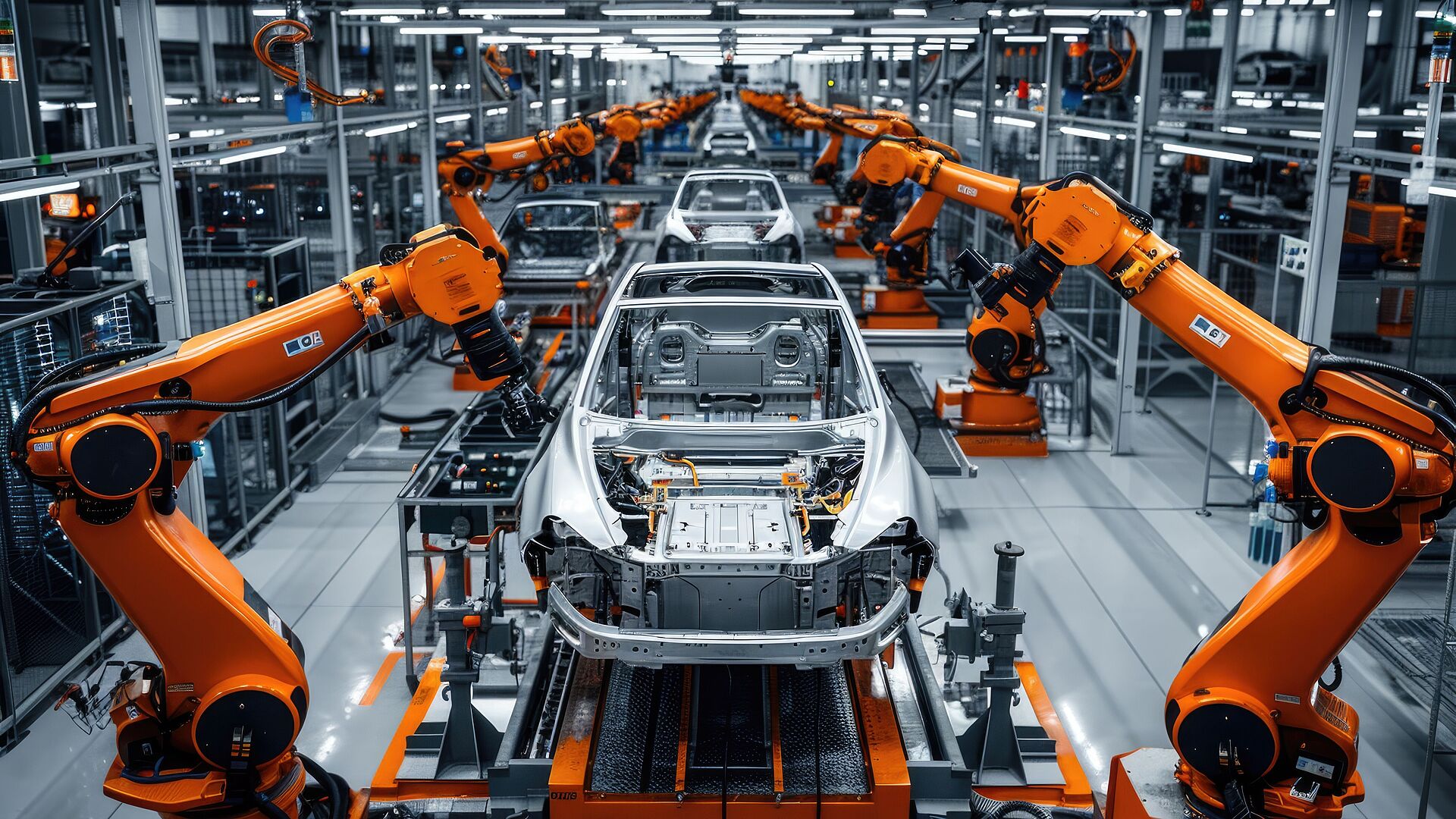

Press-hardenable steels have been used since the mid-1980s to produce high-strength structural components in lightweight automotive construction. Since then, they have played an important role in meeting increasingly stringent safety regulations and climate targets. The number of components produced each year has been steadily increasing since the process was introduced. While 3 million parts were manufactured per year in 1987, the number of parts manufactured in 2017 is already estimated at 300 million. Modern car bodies have a proportion of press-hardened components of up to 40% of the total mass of the BIW. This illustrates the relevance of the process for the automotive industry and the importance it has for the production of lightweight, durable body components.

In the industrial press hardening process, the blanks are usually heated in a continuous furnace, such as a roller hearth furnace. Due to the heat transfer in the oven in the form of radiation and convection, heating times of up to 5 minutes are required to heat the blanks to a temperature of 950°C. To ensure that enough blanks are available to maintain the press cycle, the ovens must be designed to be long enough. This results in typical furnace lengths of more than 40 metres. In addition, roller hearth furnaces have long heating and cooling times, and strong temperature fluctuations can damage the ceramic rollers used to transport the piece goods. For this reason, the kilns are often heated even during a production shutdown to ensure smooth operation. This leads to a high energy requirement even when a production line is at a standstill.

Idea

Induction heating offers many advantages as an alternative to conventional roller hearth furnaces. Due to the heat generated directly in the component, higher heating rates and better efficiencies can be realised than with heat transfer by convection and radiation. This makes induction a space-saving and energy-efficient process for heating steel components. The process is therefore already being used industrially in the melting, forging and heat treatment of components. However, the potential of induction for heating sheet metal blanks in the press hardening process has also been increasingly investigated in recent years. A major focus of these investigations is the influence of induction heating on the homogeneity of the heating and the component properties of the sheet metal blanks.

In order to obtain industry-relevant, representative results, this innovative production process, the associated production system and the required infrastructure are to be analysed and tested in a real environment. To this end, they will be integrated into the New Mobility OWL (Neue Mobilität Ostwestfalen-Lippe) experimental area, which will also enable their early alignment with future working and living conditions. The New Mobility OWL (NeMo.OWL) cluster initiative has set itself the goal of integrating previously isolated fields of research - "mobility research", "vehicle concepts", "energy systems" and "digital ecosystems" - into an experimental space. The aim is to realise highly efficient technologies for the sustainable protection of the climate and natural resources. The provision and management of supply and demand of sustainable energy for production processes, everyday life and mobility in the experimental space is the subject of the energy platform. Various promising technology paths, such as hydrogen technology and the coupling of electricity and heating systems, are being investigated. Sector coupling is also particularly attractive, as the proportion of electricity generated from renewable sources in the Paderborn district was already over 100% in 2018 [HSH18]. The entire experimental space is mapped in a digital ecosystem that enables the planning, coordination and operation of the overall system. Based on the research results, new products can be developed in a complete system environment so that the interaction of a new product with its system environment can be incorporated into the development process. This leads to innovative, customised products and thus to high utilisation and implementation potential. Over 50 network partners under the leadership of Paderborn University have come together so far to make the New Mobility OWL a showcase project for NRW through experiments and applications.

Research objectives

Construction of a production line for the press hardening of sheet metal components with inductive heating and production of demonstrator components

The aim is to demonstrate the suitability of the overall concept for series production. The production line is to be designed with energy efficiency in mind. The advantages of an induction system in terms of space requirements are to be utilised in order to enable the most effective system layout possible, taking into account transport, heating and forming.

Implementation of the production line in the New Mobility OWL experimental space

Using a virtual twin of the energy system of the entire experimental space, an optimisation algorithm is modelled which represents an energy management system for coordinating the power flows. This should enable optimal utilisation of renewable energies based on the news and future weather conditions, available energy storage and the production plan. In addition, the energy infrastructure of an inductively operated press hardening line is to be developed. This will be implemented in the regenerative energy network of Neue Mobilität OWL on the basis of the energy management system.

Determination of business and operating models for an induction press hardening line

Closely linked to the energy management system, operating modes for plant operation are to be determined here. The aim is to develop a system that enables optimised, energy-efficient and economical production of components in communication with machine sizes, energy management and the order situation.

Balance sheet analysis of an inductively operated press hardening line

The energy and raw material requirements for the production of components are also to be determined and compared with existing production methods. The aim is to demonstrate the ecological and economic advantage of a production line powered by renewable electricity compared to the use of fossil fuels. In line with the increasing demand for supply chain responsibility, upstream processes for the provision of the necessary resources are also to be taken into account.